Give Disposable Booties the Boot with YULEYS® Industrial-Grade Reusable Footwear Covers!

Wearing YULEYS® reusable shoe covers on the job results in increased worker safety, reduced operational costs and an environmentally-friendly footprint. Try a hands-free fit — just slip your boot or shoe into one and start work. You’ll discover that you can walk on an aircraft wing or any other sensitive surface with the confidence that your footwear will protect you both, all day long.

- Compatible with steel toed and non-steel toed work boots and work shoes

- Easily slip them on and off without bending over or using your hands

- A Snug fit with its unique heel-lock system that keeps them in place

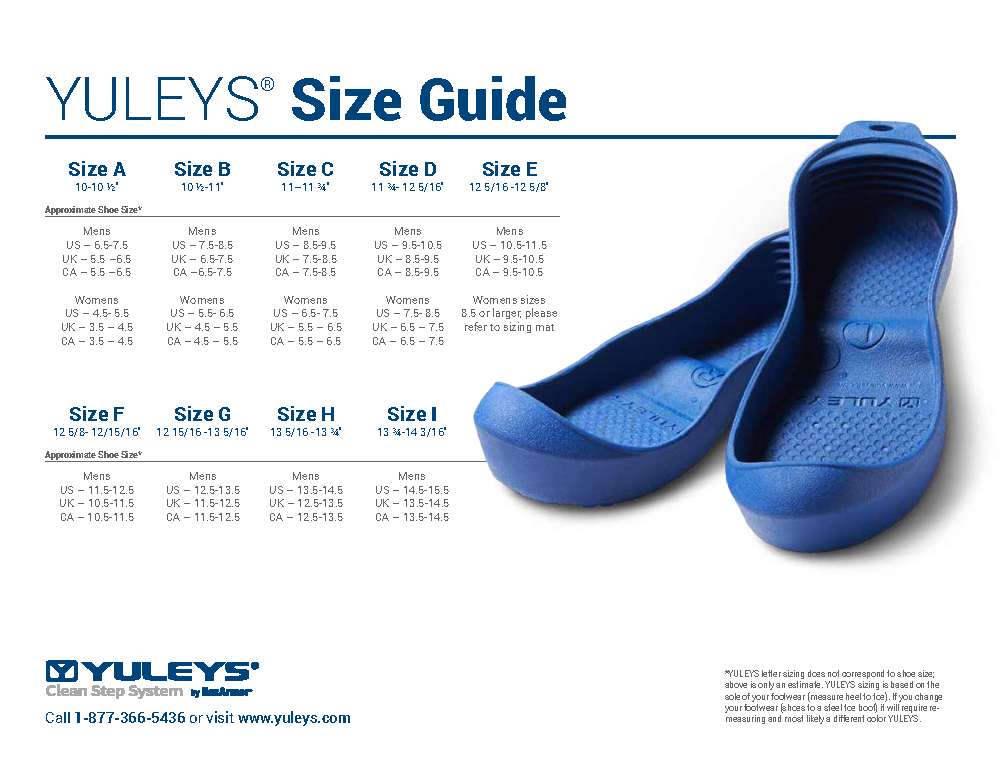

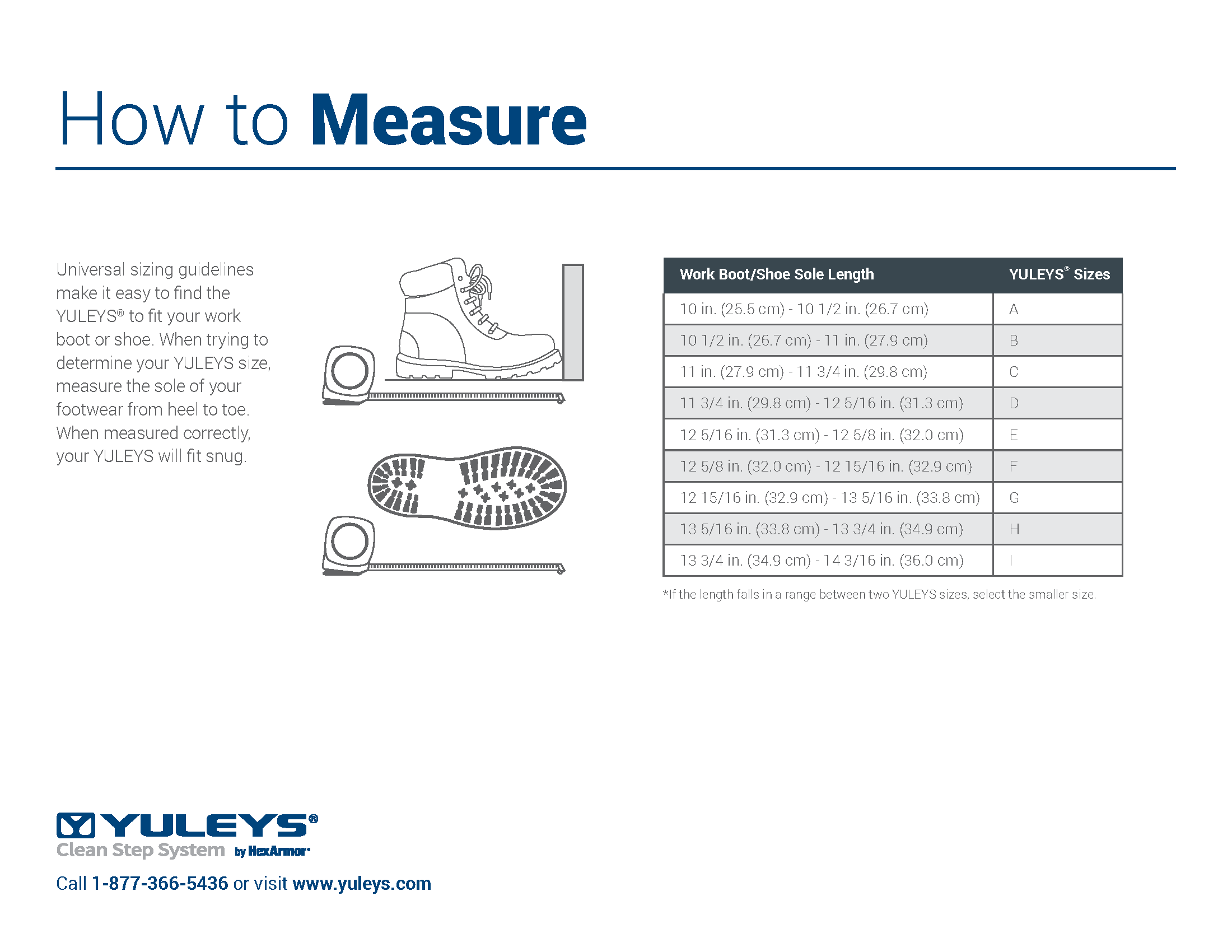

- A personal fit that comes in different sizes to match your boot

- Greater sole traction with fewer slips and greater piece of mind

- Durable, made from industrial-grade thermoplastic resin

- Reusable, wear the same pair over and over again

- Washable in soap-and-water, the laundry, or even the dishwasher

- Cost-effective, no more buying boxes and boxes of disposables

- Recyclable, yet another reason to feel good about wearing them

Case Study: There’s No Such Thing As Clean Enough in Aerospace

A leading defense aerospace engineering company turned to YULEYS® to protect their aircraft from foreign object damage (FOD). Sophisticated aircraft must be kept in pristine condition, especially the wings, so a thin film or “skin” is applied to the surface to prevent scratches or other damage. However, aerospace workers sometimes need to walk on the aircraft to perform their tasks. This skin can be easily damaged by footwear — if one scratch cuts through and damages the wing surface, the entire skin must be reapplied at great cost.

A worker at the company, who was wearing disposable booties over work boots, was walking on the wing of an aircraft when a stone stuck in the tread cut through the bootie and skin, and into the actual wing surface. The cost of repairs, including down time, was reason enough for the company to reconsider the use of disposable booties. The manufacturer worked directly with the company to implement a YULEYS Clean Step Program on a single aircraft assembly. This proved to be successful, and was soon expanded into other assembly areas.

Following these trials, the company approved the site switch to YULEYS as the only shoe cover their workers could use. This company trusts YULEYS so much that they are now experimenting with removing the protective skin altogether. This could translate into a significant reduction in the total assembly time for each aircraft. They now hope to speed up the total manufacturing turnaround time for an aircraft, which would deliver significant cost savings.